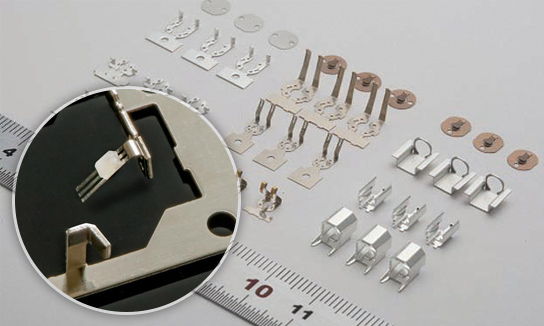

Hashimoto Precision is a metal stamping company, specializing in precision metal stamping, metal bending, and produce a wide range of metal stamping part, including our most famous aluminum bike frames.

What is Metal Stamping?

Metal stamping is the process of creating 2D shapes from thin metal sheets. The process involves using a die, which is a negative image of the desired shape, and a punch, which is the positive image. The die and punch are placed on opposite sides of the metal sheet, forcing the punch into the die, creating the desired 2D shape.

Metal stamping can be used to create a variety of shapes, including coins, keys, jewelry, and more. The process is often used for mass production because it is relatively quick and easy.

How does a Metal Stamping Work?

A metal stamping parts is a tool used to create impressions on metal objects. The stamping comprises two parts: the body and the die. The body of the stamping part is inserted into the die, and then the die is struck with a hammer to create the impression.

Metal stamping is a process that has been used for centuries to create everything from coins to artwork. Metal stamping is still used for various applications, including creating identification tags, jewelry, and other decorative items.

Quotes for Metal Stamping Services

The three most important factors that will affect the price of your metal stamping project are the design size, the number of impressions, and the type of finish. Let’s take a closer look at each of these factors:

- Size: The size of the design is directly related to the amount of time it will take to create the stamp. The larger the design, the more time it will take and, therefore, the higher the price.

- Several impressions: The number of times the design is stamped into the metal will also affect the price. A single impression is the least expensive, while multiple impressions are more expensive.

- Finish: The types of finish applied to a stamping project will also affect the price. Polishing and anodizing are two options, with polishing being the least expensive and anodizing slightly more costly.

Pagalsogns.me

Pagalsogns.me